We provide a knowledge base and service range matched by few machining specialists.

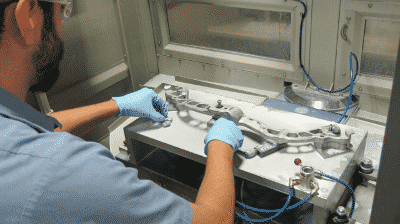

CWM offers both conventional and CNC machining capabilities.

Depending on your requirements, we can customize a machining process to meet your specifications and budget.

- CNC Machining Services: 25 centers including vertical, horizontal, drill & tap, and turning. Our CNC department maintains its own dedicated engineering staff and QA laboratory.

- CNC Prototypes: CWM’s in-house CNC prototyping capability can work directly from a CAD file to produce precise multiple prototypes in Al, Mg or Zn for a variety of functional tests. Learn more about CWM’s prototype capabilities.

- Conventional Machining: 26 dedicated drilling, tapping and reaming machining centers in a combination of both single and multi-station configurations. With this versatility, CWM can perform a variety of machining options at a cost savings over traditional CNC machining.

Contact Chicago White Metal for more information on our in-house die casting machining services.

Learn More About Machining:

For users of machined parts looking for opportunities to reduce part costs while improving existing designs, with lower environmental impacts. Narrated webinar covers die cast conversion benefits and when such conversions are and are not advantageous. Tips on how best to make the transfer to an optimized die cast part. Covers conversion design considerations, alloys, and surface finishes— with case studies. 30 minutes. |

This overview for OEM designers and specifiers is a refresher for those OEM product design engineers, buyers, and purchasing managers already familiar with die casting. For those new to the process, it provides a valuable framework or further pursuit. View the PDF: The Die Casting Process: An OEM Designer’s Overview |

6-page guide outlines ten key cost drivers that design engineers can leverage during the product design stage to yield significant cost savings in the custom production of die cast components. These specific planning steps aid in integrating the realities of die cast manufacturing. View the PDF: 10 Ways to Reduce the Costs of Die Cast Parts |

4-page condensed overview of Chicago White Metal Casting capabilities in Al, Mg, and Zn from front-end assistance, prototyping to part finishing, and assembly. Summarizes CWM’s experience, advanced technologies, and ISO 9001 & 14001 registered management systems. View the PDF: Overview of CWM Die Casting & Production Capabilities |

16-page, full-color comprehensive brochure on Chicago White Metal Casting capabilities in the most widely specified die casting alloys— Al, Mg & Zn. From design assistance through production, post-casting machining, surface finishing, and final product assembly. Detailed overview covers the experience, advanced technologies, and ISO 9001 & 14001 registered management systems that make CWM the cost-effective choice for net- and near-net-shape die cast parts. Includes case examples. View the PDF: CWM Comprehensive Die Casting Capabilities Brochure |

2-page descriptive detailed data sheet for Chicago White Metal Casting’s current high-tech production specifications, material properties, and nominal chemistry for its Al, Mg & Zn alloy capabilities. View the PDF: CWM Al, Mg & Zn Die Cast Production Specs |

8-page, full-color brochure on CNC capabilities for machined prototypes in all metals, as well as plastics, for form, fit and functional testing; post-casting CNC machining; and low- to high-volume CNC part production, including screw machining. View the PDF: CWM CNC Machining Capabilities Brochure |

This in-depth White Paper from the North American Die Casting Assn. details of how collaborative engineering between OEM engineers and custom die caster engineering can result in improved production efficiencies and reduced part costs. The case study method is used to discuss cost-saving opportunities for existing parts at the point of tooling replacement or required product design revisions, as well as for clean sheet designs. View the PDF: NADCA Collaborative Engineering White Paper |

Updated and expanded 16-page reference to the superior design & specification steps that drive the cost and performance of components die cast in Al, Mg, and Zn alloys. Among essential design and production factors covered: Matching material properties; Die design & construction; Minimizing part porosity; Optimizing part heat transfer; Preplanning post-casting machining, if required; Dimensioning and tolerancing; Flash considerations; Prototyping; and as-cast finish guidelines. View the PDF: Design & Specification Guide for Custom Die Castings |

World leader in global positioning systems selected Mg die castings for the key housing components in their new optical surveying instrument. Machined parts were rejected as cost prohibitive; plastic would not provide the required stiffness for highly accurate readings. View the PDF: Key High-Tech Mg Parts for Optical Survey System |

A value analysis of alternate production efficiencies for a low-volume CNC machined brass small component for a medical device resulted in a miniature zinc net-shape die cast replacement at a 500% unit cost saving. View the PDF: Replacement for Machined Brass at a 500% Savings |

Al alloy selection, machining and finishing data; chemical composition; material properties and die casting and other characteristics. View the PDF: NADCA Standards: Aluminum Alloy Data |

Mg alloy selection, machining and finishing data; chemical composition; material properties and die casting, and other characteristics. View the PDF: NADCA Standards: Magnesium Alloy Data |

Updated Zn and ZA alloy selection, machining and finishing data; chemical composition; material properties and die casting and other characteristics. View the PDF: NADCA Standards: Zinc & ZA Alloy Data |

This presentation will aid OEM product designers, engineers, and specifiers with valuable, practical guidelines for assuring sound design-for-manufacturing decisions before freezing their designs destined for die casting production. View the PDF: Leveraging DFM Before Design Commitment |

Machining to Die Casting: A Guide to Conversion

Machining to Die Casting: A Guide to Conversion The Die Casting Process: An OEM Designer’s Overview

The Die Casting Process: An OEM Designer’s Overview 10 Ways to Reduce the Costs of Die Cast Parts

10 Ways to Reduce the Costs of Die Cast Parts Overview of CWM Die Casting & Production Capabilities

Overview of CWM Die Casting & Production Capabilities CWM Comprehensive Die Casting Capabilities Brochure

CWM Comprehensive Die Casting Capabilities Brochure CWM Al, Mg & Zn Die Cast Production Specs

CWM Al, Mg & Zn Die Cast Production Specs  CWM CNC Machining Capabilities Brochure

CWM CNC Machining Capabilities Brochure NADCA Collaborative Engineering White Paper

NADCA Collaborative Engineering White Paper Design & Specification Guide for Custom Die Castings

Design & Specification Guide for Custom Die Castings Key High-Tech Mg Parts for Optical Survey System

Key High-Tech Mg Parts for Optical Survey System Replacement for Machined Brass at a 500% Savings

Replacement for Machined Brass at a 500% Savings NADCA Standards: Aluminum Alloy Data

NADCA Standards: Aluminum Alloy Data NADCA Standards: Zinc & ZA Alloy Data

NADCA Standards: Zinc & ZA Alloy Data Leveraging DFM Before Design Commitment

Leveraging DFM Before Design Commitment