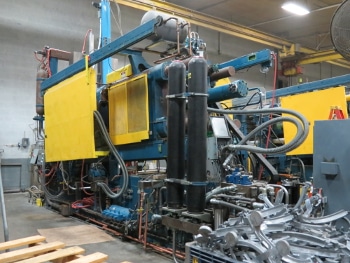

Hot Chamber Die Casting for high volume processing of complex shaped components in magnesium or zinc.

The hot chamber die casting process is used at CWM for both our magnesium and zinc production. With this method, molten metal is automatically supplied to the die cast machine via a “gooseneck” that is submerged in furnace full of molten metal. At the beginning of the cycle, a piston is retracted, allowing the gooseneck to fill with molten metal. The piston is activated and metal is plunged through the gooseneck and into the die.

- Faster-cycling production

- Intricate cast-in detail

- Reduced porosity

- Longer die casting die life due to lower melting points

- Die design efficiencies = waste reduction

CWM was the first North American die caster to use the magnesium hot chamber die casting process and is the largest custom production facility of its kind in North America. With 10 magnesium die casting centers and two of the world’s largest magnesium hot chamber die casting machines, we can produce magnesium parts in a range of sizes from 0.75” x 0.75” to 18” x 18”. (19mm x 19mm to 457mm x 457mm).

Our zinc die casting department can produce parts in a range of sizes from 0.75” x 0.75” to 18” x 18”.

Request a quote today on hot chamber die casting for your application, or contact Chicago White Metal to review your project.